Now in SIGMASOFT® Elastomer

With the SIGMASOFT® Elastomer module, SIGMASOFT® now offers the possibility to simulate one of the oldest processes: Compression Molding.

The simulation mode Compression Molding allows viewing your process including the mold and receiving all results you are used to from the injection molding simulation in SIGMASOFT®.

INCREASING THE EFFICIENCY OF YOUR PROCESS IS CHALLENGING SINCE THERE IS MORE THAN only ONE ADJUSTABLE SCREW:

- Placement and shape of the preforms

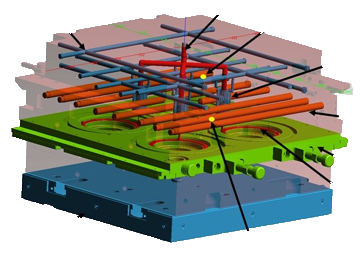

- Position, number, and power of heating cartridges

- Optimization of heating time

- Identification of cold spots in the mold

- Examination of the filling of all cavities and position of air pockets

- Time pressure!

Lay out the entire mold effortlessly and examine the cavity filling, the compression process, as well as the influences of flow front formation and fountain flows. Last but not least, high-quality 3D technology allows you to identify air pockets, evaluate the influence of heating cartridges, and view post-curing outside the mold.

SIGMASOFT® Compression Molding SUPPORTS THE SOLUTION OF COMPLEX QUESTIONS IN COMPRESSION MOLDING FROM DESIGN TO PROCESSING.

WHAT YOU CAN EXPECT FROM SIGMASOFT® Elastomer WITH COMPRESSION MOLDING:

- Predict cavity filling and compression process

- Predict flow front propagation, fountain flow, block shear flow, and jetting effects

- Calculate curing and scorch already during the filling phase

- Predict shear gradients

- Calculate low viscosity elastomers

- Consider curing-dependent viscosity, curing time, and curing rate at any area of the part

- Simulate electric cartridge heaters/heating coils using PI control

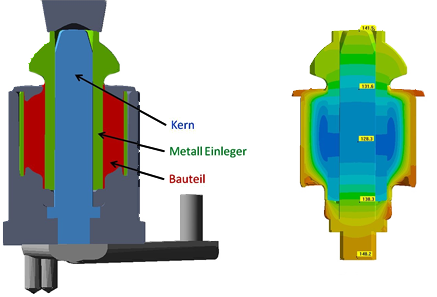

- Analyze the influence of inserts on mold filling and curing reaction, such as preheating and materials

- Predict post-curing outside the mold and tempering processes

MAKE SIGMASOFT® YOUR TOOL AND...

... YOU WILL GET MORE OUT OF YOUR PROJECTS!

OUR IN-HOUSE DEVELOPMENT AND THE TEAM OF EXPERIENCED ENGINEERS IS YOUR SERVICE!

Successful injection molding simulation requires the direct contact between the users and a competent engineering team. Therefore, our solution service, our customer support as well as our application-oriented software developers work closely together with you for your success!

YOUR INSIGHT INTO OUR CASE STUDIES:

Casestudy

ELASTOMER TROUBLESHOOTING:

THE INFLUENCE OF INSERT PREHEATING

Casestudy

HOW RELEVANT IS TIME IN INJECTION MOLDING?

Casestudy

THERMAL ANALYSIS DELIVERS FIRST-SHOT-SUCCESS IN RUBBER INJECTION MOLDING